Home > Product > Copper Hollow Conductor

Copper Hollow Conductor is a new product line recently added to our portfolio of Copper Busbar and Copper Bar products.

Copper Hollow Conductor is a new product line recently added to our portfolio of Copper Busbar and Copper Bar products.

The centre 'Copper Hollow Conductor' can allow coolants to be passed within the busbar. This hollow feature, together with the coppers superb electrical and thermal properties offer the highest specification demanded by today's Electrical power generation and distribution systems, with further possible applications in industrial refrigeration, and desalination systems.

Copper Hollow Conductor are available in a variety of cross-sections from complex to standard profile shapes. As with all our existing products it is available OC-ETP® material and various other copper alloys.

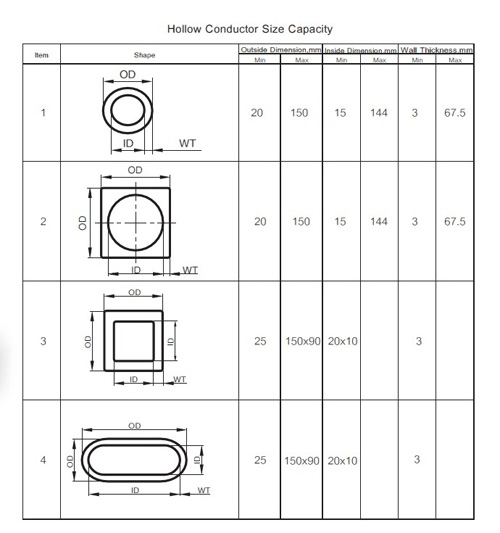

- Hollow Conductor Size Capacity

- Standard Industry Grades

UNS No.

Chemical Composition

C11000Electrolytic tough pitch copper

99.90 Cu 0.04 O

C11300

C11400

C11500

C11600Silver-bearing tough pitch copper

99.90 Cu 0.04 O 0.025 Ag

99.90 Cu 0.04 O 0.031 Ag

99.90 Cu 0.04 O 0.050 Ag

99.90 Cu 0.04 O 0.078 Ag

C12000

C12100

C12200Phosphorus-deoxidized copper

99.90 Cu 0.008 P (DLP)

99.90 Cu 0.008 P 0.125 Ag

99.90 Cu 0.02 P (DHP)

C14500

C15000

C16200

C17000

C17200

C17300High copper alloys

99.5 Cu 0.50 Te 0.008 P

99.8 Cu 0.15 Zr

99.0 Cu 1.0 Cd

98.1 Cu 1.7 Be 0.20 Co

97.9 Cu 1.9 Be 0.20 Co

97.7 Cu 1.9 Be 0.40 Pb

- Other applications

High energy magnets, Particle accelerators, Plasma research devices, i-on implantation units for micro circuit industry, MRI medical devices, etc.

- Applications of Copper Hollow Conductor:

Induction Furnace

Induction Furnace

Induction heating

Induction heating

Accelerator Magnet Coils

Accelerator Magnet Coils

Power Generators

Power Generators

Switchboard/Switchgear

Switchboard/Switchgear

Heat Exchangers

Heat Exchangers

Radiators

Radiators

- Available Shapes

Oriental Copper manufactures conductor in accordance with customer specifications.

- Benefits of Copper Hollow Conductor:

Superior electrical and thermal conductivity

Superior electrical and thermal conductivity

Superior structural integrity

Superior structural integrity

Excellent mechanical properties

Excellent mechanical properties

High creep resistance

High creep resistance

- Production Process

The Conductor sections are manufactured by extrusion and drawing processes. They have a shiny, smooth surface and are excellent for further machining