Home > Product > OC-ETP® - 正确的选择!

OC-ETP® - 用正确的材料得到正确的解决方案

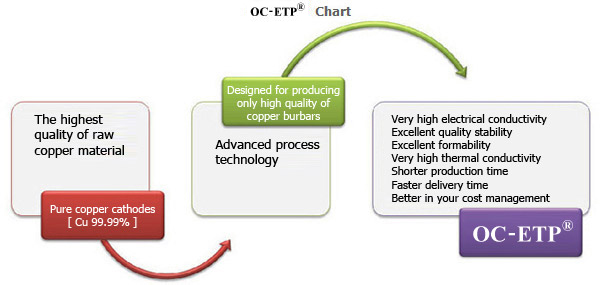

铜汇流排的电气应用有几项主要的电气与机械性能需求,包括高导电性、高强度、成型良好、表面平整。这些主要特性极大地依赖于原料品质与加工程序的一贯性。透过专为铜汇流排设计的特殊先进工艺,我们将矿冶界所能觅得最高纯度的纯铜阴极原料(A级 LME 注册品牌)铸造成OC-ETP®。高纯度材料加上高品质的生产工艺,使得OC-ETP®适用於铜汇流排与铜汇流导管电气应用的所有技术性及经济性解决方案。此外,OC-ETP®还能提供优异的热传导性,极适合如CPU散热片这样的空间有限的热交换应用。

- Right Conductivity

Electrical conductivity of any electrical conductor is dependent upon the purity of conductor. OC-ETP® is cast from pure copper cathodes with a purity of 99.99 %. This high purity of raw material enables OC-ETP® to achieve an electrical conductivity 101% IACS (International Annealed Copper Standard).

- Right Formability

Formability is a term used to express how well a copper busbar can be bent without cracking. OC-ETP® material can be formed into superbly fabricated finished products, all bends are smooth with no surface cracking. This is because OC-ETP® has good formability. The formability of copper is directly related to the grain size structure of the copper material - the smaller the copper grains the better the formability, this is expressed as the minimum bend radius (R) divided by the thickness (t).- Hence, the smaller the R/t, the better the formability. OC-ETP® process produces a very fine copper grain size structure, offering superior formability.

- Right Flatness

The Flatness of a copper busbar is vital for jointing efficiency. The better the flatness, then no or less machining work is required during preparation of the jointing surfaces. OC-ETP® material has less than 50 μm flatness tolerances, which makes OC-ETP® busbar surfaces excellent for joining together effectively.

- Right Quality

With a very high copper purity (99.99%) of our raw materials, computerised control systems and our special process to homogenize our billets' temperature, the microstructure of OC-ETP® material produces copper material of exceptional quality.

- Right Production Process

OC-ETP® is produced by a state-of-the-art production process, specifically designed to produce copper busbar of the highest quality. Our processes result in copper material with the finest copper grain size, high conductivity, mechanically strong, good formability and with an exceptionally flat, shiny aesthetic finish. - Production of OC-ETP® is very flexible, switching production to a different cross-section takes just a few minutes enabling OC-ETP® to be produced in small quantities and of different sizes quickly. This makes OC-ETP® the perfect choice for short lead and production times making faster delivery for the benefit of our customers.

- Right Thermal Conductivity

Thermal conductivity is particularly important for electronic and IT applications. OC-ETP® is used in computer applications where thermal conductivity is paramount. OC-ETP® has a very high thermal conductivity due to the high purity of copper. Flatness control is also critical for the fine tolerances required. OC-ETP® has successfully supplied quality products to the major heat-sink producers for many years.

- Right Property for Welding and Brazing

OC-ETP® can be jointed by soldering, brazing and gas shield arc welding without adverse effects.